At Banerjee Machines & Tools Co., we take pride in becoming one of the leading industrial valve manufacturers in Kolkata, offering high-performance industrial valves designed for efficiency, durability, and precision. With over 30 years of expertise, we manufacture CNC-machined and conventionally crafted valves that meet the highest industry standards, ensuring seamless performance in diverse applications.

Get a Detailed Quote!

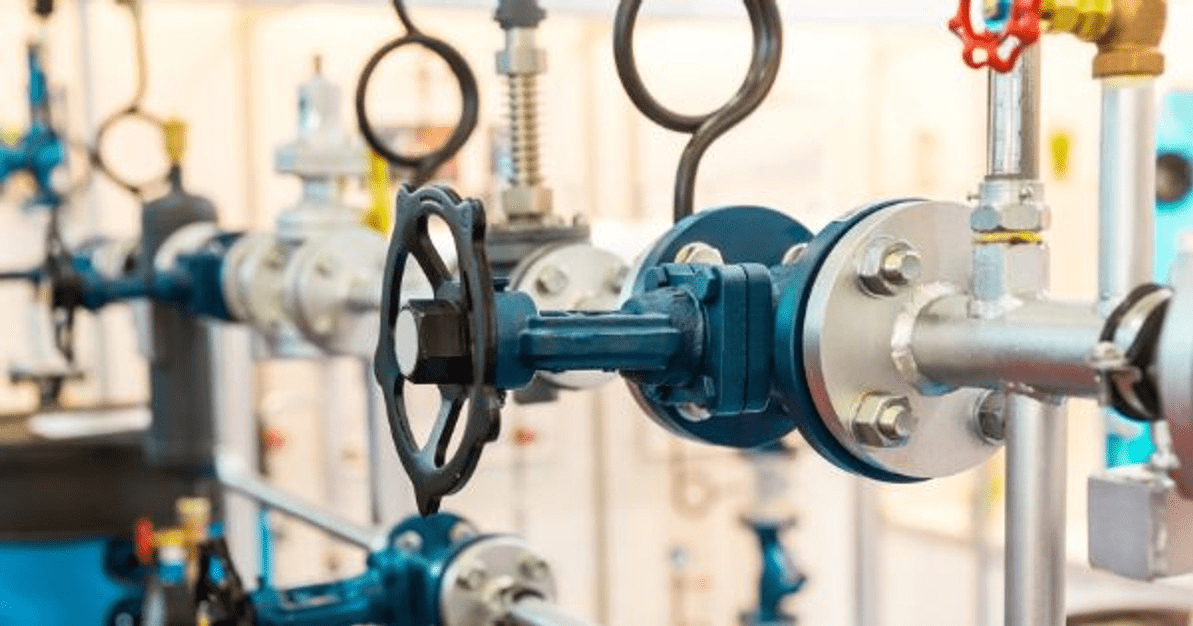

Valves are essential components used to control, regulate, and direct the flow of liquids, gases, and slurries across various industries. They function by opening, closing, or partially obstructing passageways to ensure precise flow management, pressure control, and system safety. Available in multiple types, including gate, globe, ball, and check valves, each variant is designed to meet specific operational requirements.

At Banerjee Machines & Tools Co., we specialize in manufacturing premium-quality industrial valves. Exactly what you expect from the best valve manufacturing company in India. Our valves are known for exceptional performance in demanding environments.

At Banerjee Machines & Tools Co., we are professional industrial valve manufacturers in India, providing reliable and high-performance solutions for industrial applications for over 30 years. Our advanced CNC machining, strict quality control, and premium material selection ensure that every valve meets the highest industry standards. Designed for efficiency and durability, our valves serve multiple industries, including oil and gas, power generation, chemical processing, and water purification.

Industrial Flow Control—Ensuring smooth and efficient regulation of liquids and gases.

High-Pressure Systems—Reliable performance in extreme pressure environments.

Corrosive Environments—Resistant to rust, wear, and chemical exposure for longevity.

Temperature-Resistant Operations—Engineered to function optimally in extreme heat or cold.

Custom Engineering Solutions—Designed for specific industry needs and operational efficiency.

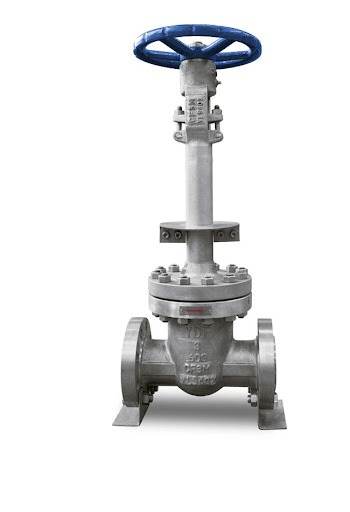

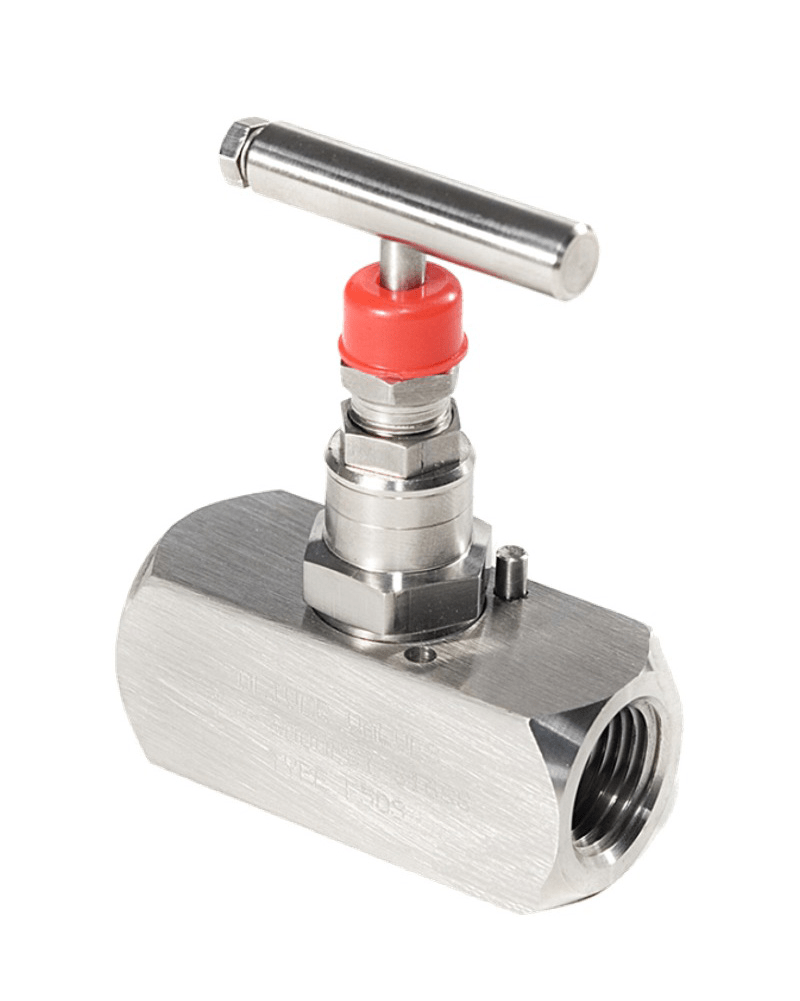

Designed for efficient flow control in high-pressure environments, ensuring durability and performance even under extreme conditions.

Pressure Rating: Up to 2500 PSI

Sizes: ½” to 24”

Materials: Forged Carbon Steel, Stainless Steel, Alloy Steel

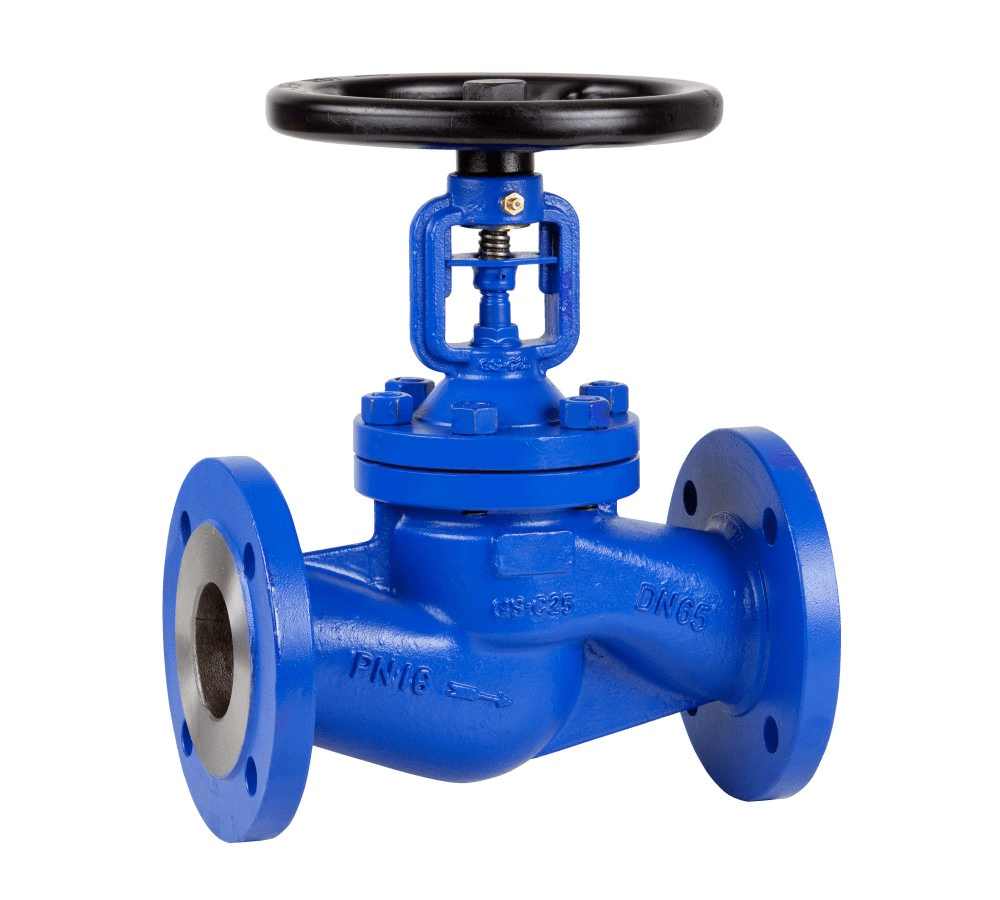

Provides precise throttling control to maintain consistent flow in various industrial applications, ideal for regulating flow at varying rates.

Pressure rating: 150 PSI to 4500 PSI

Sizes: ½” to 36”

Materials: Cast Iron, Stainless Steel, Bronze

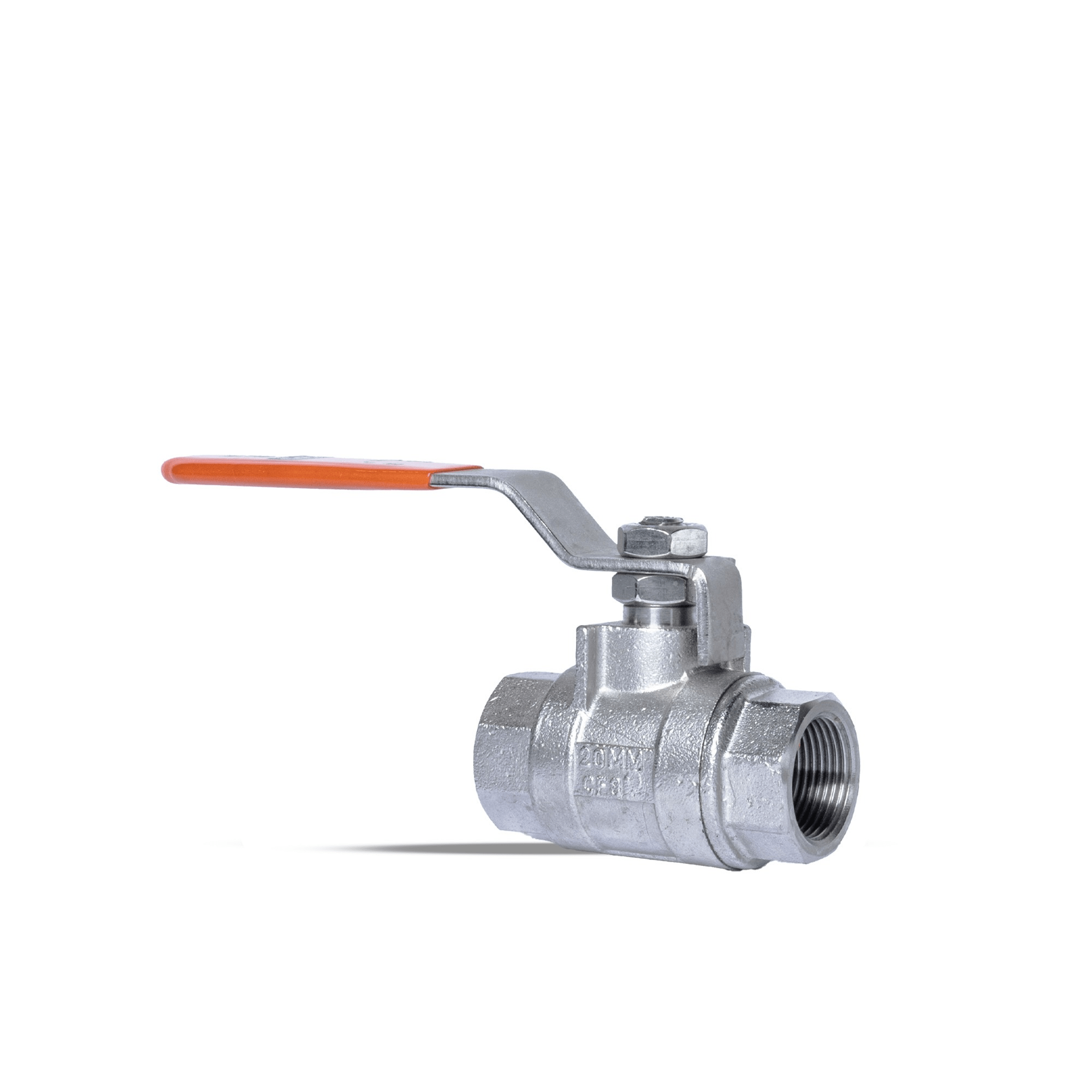

Ensures tight sealing and smooth operation, making it ideal for fluid regulation in systems that demand precision and reliability in flow control.

Pressure rating: Up to 6000 PSI

Sizes: ¼” to 48”

Materials: Carbon Steel, Brass, PTFE, Stainless Steel

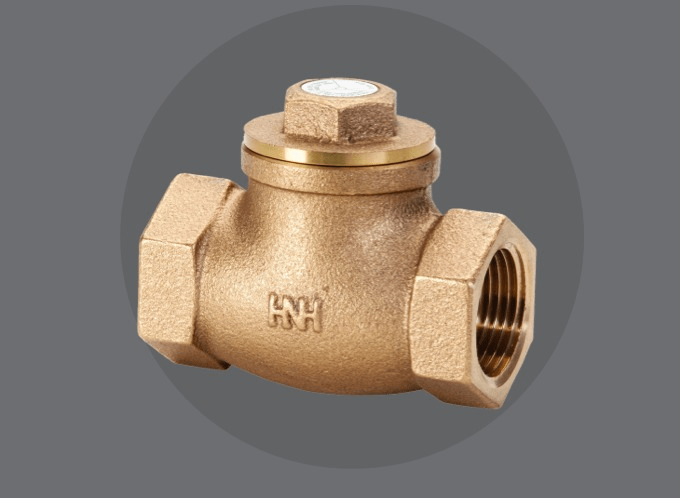

Prevents backflow, maintaining directional flow control in piping systems by ensuring fluid only moves in one direction.

Pressure rating: 200 PSI to 5000 PSI

Sizes: ½” to 42”.

Materials: Cast Steel, Bronze, Alloy Steel

A lightweight, cost-effective solution, perfect for controlling large flow systems in industries where space and cost-efficiency are important.

Pressure rating: 150 PSI to 900 PSI

Sizes: 2” to 120”

Materials: Ductile Iron, Stainless Steel, Aluminium Bronze

Designed for fast shut-off in demanding conditions, offering exceptional reliability and ease of operation in systems that require a quick response.

Pressure rating: 150 PSI to 6000 PSI

Sizes: ½” to 36”

Materials: Cast Iron, Stainless Steel, PTFE-Coated Metal

Prevents system overpressure and ensures the safety and efficiency of your equipment, automatically releasing pressure when it exceeds safe limits.

Pressure rating: 150 PSI to 5000 PSI

Sizes: ½” to 24”

Materials: Stainless Steel, Brass, Carbon Steel

Perfect for controlling highly corrosive or viscous fluids, offering durability and precise control in environments where chemical compatibility is critical.

Pressure rating: 50 PSI to 1500 PSI

Sizes: ½” to 48”.

Materials: PTFE, Cast Iron, Stainless Steel.

We follow a structured and quality-driven work process to deliver world-class valve solutions:

Understanding your requirements and creating innovative designs.

Using high-grade materials and precision CNC machining.

Conducting rigorous tests to ensure durability and efficiency.

Ensuring timely delivery with a focus on excellence.

With decades of experience in valve manufacturing and servicing, we are your trusted partner for all your valve needs. Our precision engineering, quality control, and industry expertise make us the leading choice for valve solutions.

We manufacture gate valves, globe valves, ball valves, check valves, and custom-engineered valves based on client requirements.

Our valves are used in oil & gas, chemical processing, water treatment, power plants, and various industrial applications.

Yes, we provide custom-engineered valve solutions to meet specific industry needs.

We follow a strict quality control process, including CNC precision machining and rigorous performance testing.

You can contact us directly through our website, phone, or email to discuss your requirements.

2026-02-18

By Banerjee Machine & Tools Co.

This blog explores the future of Jig Manufacturing in Kolkata, highlighting key trends, technologies, and innovations led by BMT Co. to support precision, efficiency, and evolving industry demands.

Read More

2026-02-17

By Banerjee Machine & Tools Co.

This blog explains how BMT Co., a leading Industrial Valve Manufacturer in India, ensures zero-defect gate valves through strict quality control, precision manufacturing, and advanced testing processes.

Read More

2026-02-11

By Banerjee Machine & Tools Co.

Selecting the right material is crucial for the performance, durability, and precision of CNC machined parts. This blog explores key factors to consider, with expert insights from CNC Machining Service in Kolkata specialists at BMT Co.

Read More