From concept to creation, we bring your ideas to life with cutting-edge manufacturing expertise.

By Banerjee Machine & Tools Co. |

Published on | 5 min read

Enhance your industrial knowledge with our detailed breakdown of how gate valves work.

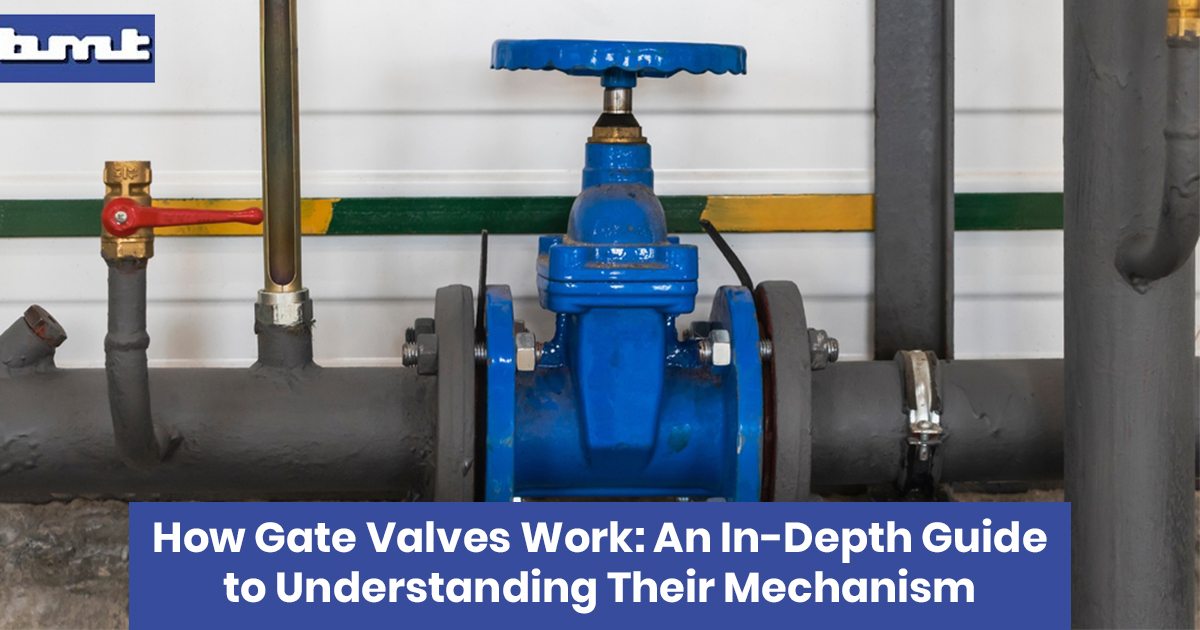

In industries where controlling the flow of liquids or gases is essential, gate valves are among the most widely used and reliable types of valves. From oil refineries to chemical processing plants and water treatment facilities, gate valves play a pivotal role in managing complex fluid systems.

At Banerjee Machines & Tools Co., a trusted valve manufacturer in Kolkata, we understand the value of precision-engineered valves in critical applications. In this blog, we take you through the working mechanism of gate valves, their industrial significance, and why choosing a quality valve manufacturer matters for long-term operational success.

A gate valve is a linear-motion valve designed primarily to start or stop fluid flow. Unlike control valves, gate valves are not typically used to regulate flow; instead, they are designed to be either fully open or fully closed. When open, the gate is lifted out of the path of the fluid, allowing an uninterrupted and low-resistance flow. When closed, the gate is lowered into place, effectively stopping the flow altogether.

Gate valves are preferred in many industrial systems because of their simple design, minimal pressure loss, and reliable shutoff capabilities.

The functioning of a gate valve is relatively straightforward, yet highly efficient for a wide range of applications. Here’s a closer look at the working parts:

1. Gate or Wedge

The central component of the valve is the gate, also known as the wedge. It moves vertically within the valve body to either allow or block flow. The gate may be made of stainless steel, cast iron, or other corrosion-resistant materials, depending on the application.

2. Stem

The gate is connected to the stem, which is rotated manually (via a handwheel) or through an actuator. When the handwheel is turned, the stem moves up or down, raising or lowering the gate.

3. Valve Body

This is the outer shell of the valve that houses the internal components. It must be able to withstand high pressures, temperatures, and corrosive environments.

4. Seat

When the gate is fully lowered, it rests against the valve seat to form a tight seal that prevents leakage. The seat can also be hardened for better wear resistance in demanding systems.

There are several types of gate valves depending on the gate design and the stem operation:

At Banerjee Machines & Tools Co., we manufacture a wide range of gate valves suitable for both low-pressure and high-pressure environments, with customisation available based on your operational needs.

Gate valves are integral to industries that require safe and reliable shutoff mechanisms. Some common applications include:

Gate valves offer several advantages that make them suitable for demanding industrial environments:

When sourced from a reliable valve manufacturer in Kolkata like Banerjee Machines & Tools Co., you also benefit from precision machining, quality assurance, and expert consultation tailored to your industry.

With over 30 years of experience in machining and component manufacturing, Banerjee Machines & Tools Co. stands out as a leading name in industrial valve production. Based in Baranagar, West Bengal, we combine traditional craftsmanship with modern CNC technology to deliver valves that meet stringent industry standards.

As a dedicated manufacturer, we work closely with industrial clients to provide customised valve solutions that prioritise performance, safety, and long-term value. Whether you’re looking for standard gate valves or need bespoke designs for specific applications, our team is equipped to deliver.

Understanding how gate valves work helps industries make informed decisions about flow control systems. Their reliable shutoff capability, minimal maintenance requirements, and durability make them a preferred choice across multiple sectors.

If you're seeking high-quality gate valves backed by decades of manufacturing expertise, Banerjee Machines & Tools Co. is your go-to valve manufacturer in Kolkata. Explore our full range of industrial valves and machining solutions by exploring our website or contacting our team for a consultation.

2025-06-10

By Banerjee Machine & Tools Co.

Explore the best use cases for turning, milling, and grinding in manufacturing. Banerjee Machine & Tools Co. helps you choose the right process.

Read More

2025-06-05

By Banerjee Machine & Tools Co.

Learn how to pick the perfect process—Injection Moulding vs CNC Machining—based on your project needs. Banerjee Machine & Tools Co. is here to guide you!

Read More

2025-05-27

By Banerjee Machine & Tools Co.

Jig manufacturing is evolving with sustainability in focus. Discover what it means for your industry at Banerjee Machine & Tools Co.

Read More